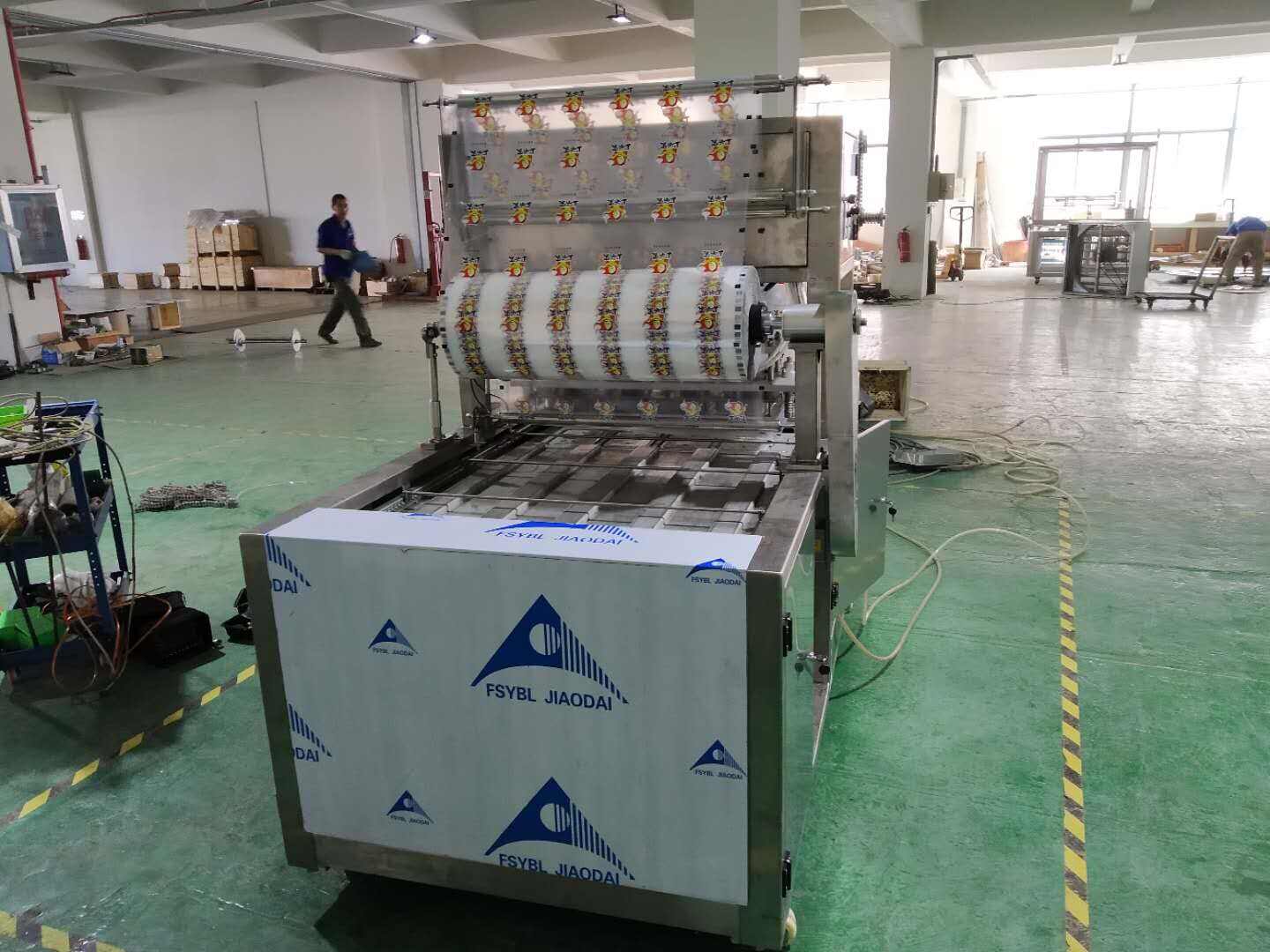

aluminum foil sealing machine

The aluminum foil sealing machine is a versatile piece of equipment designed to seal products in aluminum foil packaging, ensuring their freshness and extending shelf life. Its main functions include heat sealing various types of aluminum foil containers, such as trays and pouches. Technological features of this machine include precise temperature control, which allows for consistent sealing quality, and an adjustable speed control that caters to different production capacities. It also incorporates advanced sensors for automatic positioning, ensuring accurate sealing even on irregularly shaped containers. Applications of the aluminum foil sealing machine span across industries such as food and beverage, pharmaceuticals, and cosmetics, making it an indispensable tool for manufacturers aiming for high-quality packaging solutions.