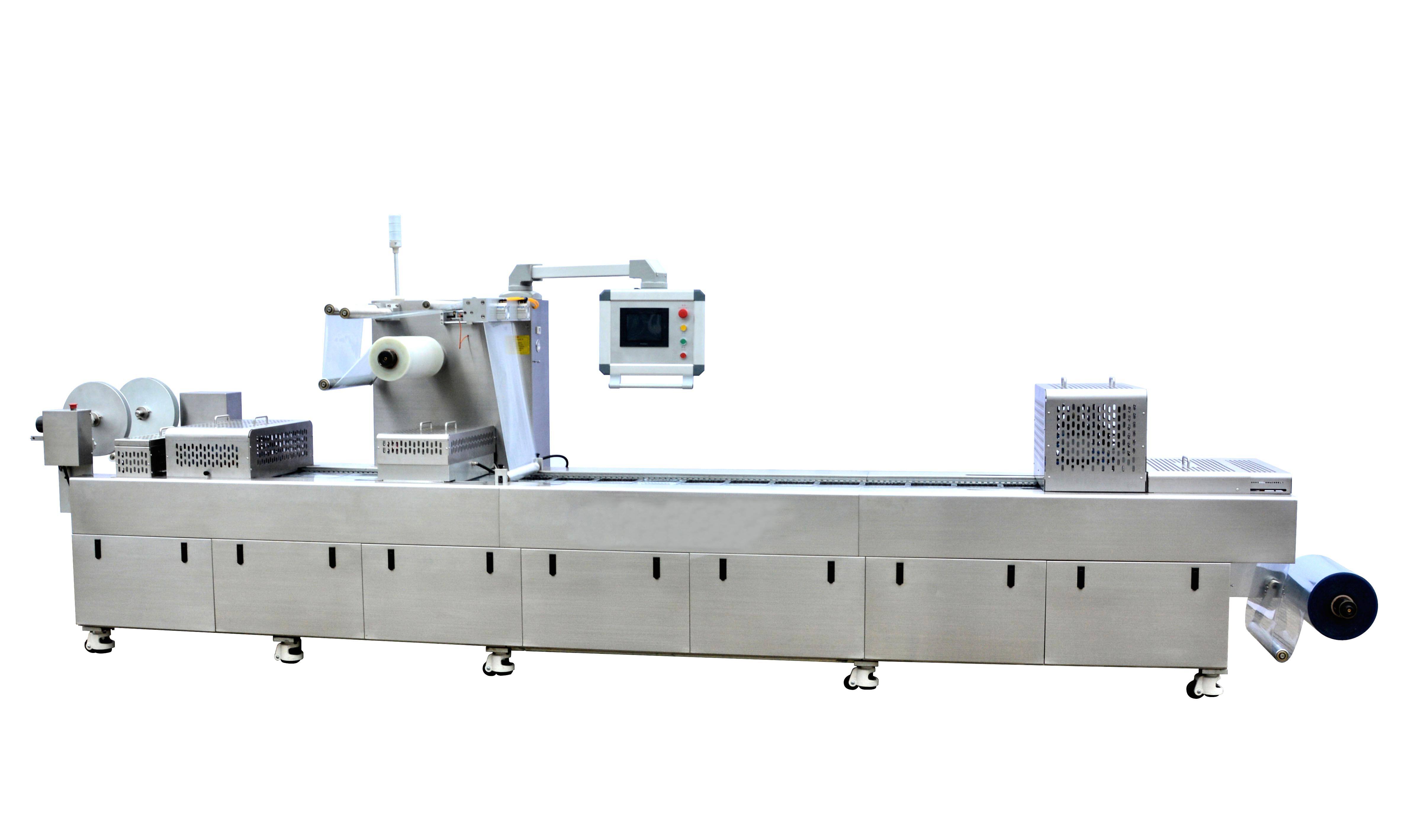

cup filling sealing machine

The cup filling sealing machine is a state-of-the-art piece of equipment designed to automate the packaging process for liquid and semi-liquid products. Its main functions include precise cup placement, consistent filling, and secure sealing, all of which are vital for maintaining product quality and extending shelf life. Technological features such as a user-friendly touch screen interface, programmable logic controllers, and advanced sensors ensure seamless operation and easy integration into various production lines. This machine is ideal for a range of industries including food and beverage, pharmaceuticals, and cosmetics, making it a versatile solution for diverse packaging needs.