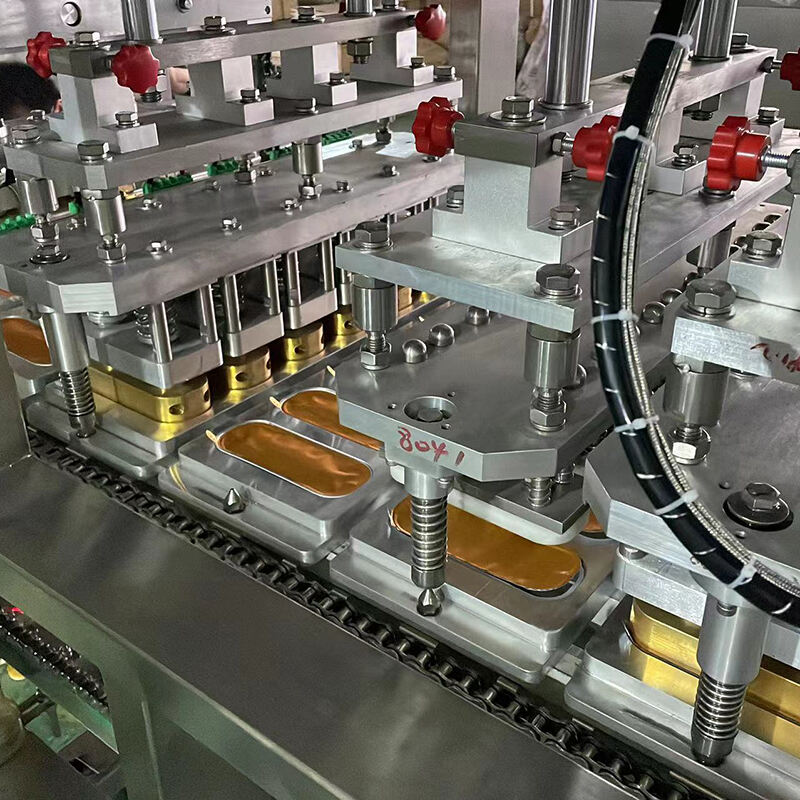

instant noodle wrapping machine

The instant noodle wrapping machine is a sophisticated piece of equipment designed to automate the packaging process of instant noodles. Its main functions include accurately portioning the noodles, sealing them in plastic or paper containers, and then wrapping these containers in branded packaging for retail distribution. Technological features of this machine include programmable logic controllers (PLCs) for precise operation, advanced sensors for product and packaging integrity, and variable speed drives for flexibility in production rates. This machine is widely used in the food industry for its efficiency and reliability in packaging a variety of instant noodle products, ensuring they are hygienic and ready for consumer use.