liquid pouch filling machine

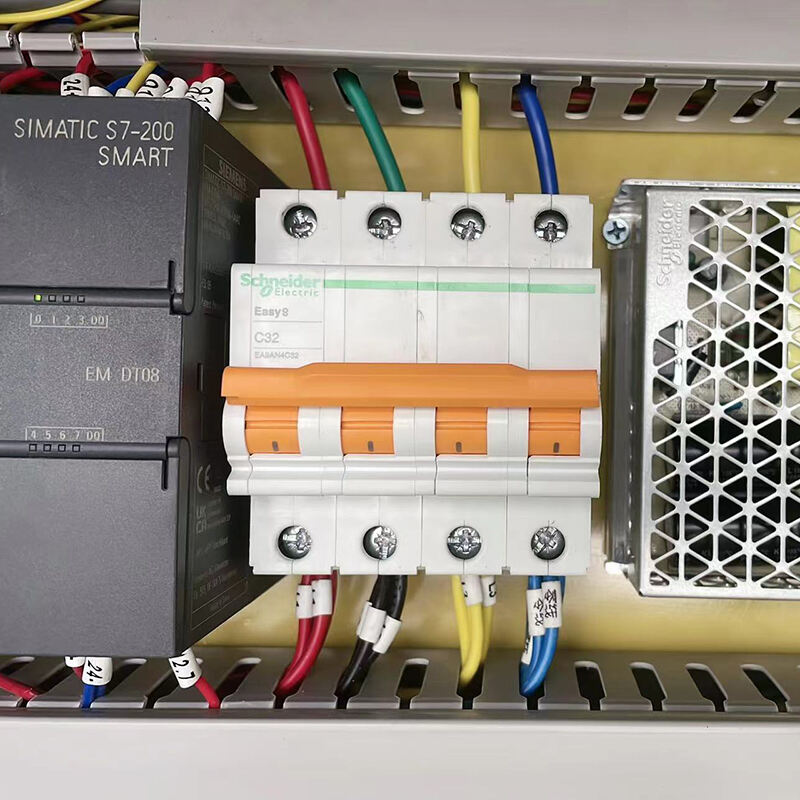

The liquid pouch filling machine is a state-of-the-art piece of equipment designed to efficiently fill a variety of liquid products into pouches of different sizes and shapes. Its main functions include precise volume measurement, filling, and sealing, ensuring that each pouch is filled to the correct specification without any leaks. Technological features of this machine include a user-friendly touch screen interface, which allows operators to easily set up and adjust the machine parameters. It also incorporates advanced sensors and a programmable logic controller (PLC) for optimized performance and reliability. The machine is suitable for a wide range of applications, from food and beverages to pharmaceuticals and cosmetics, making it a versatile solution for various industries.