spout capping machine

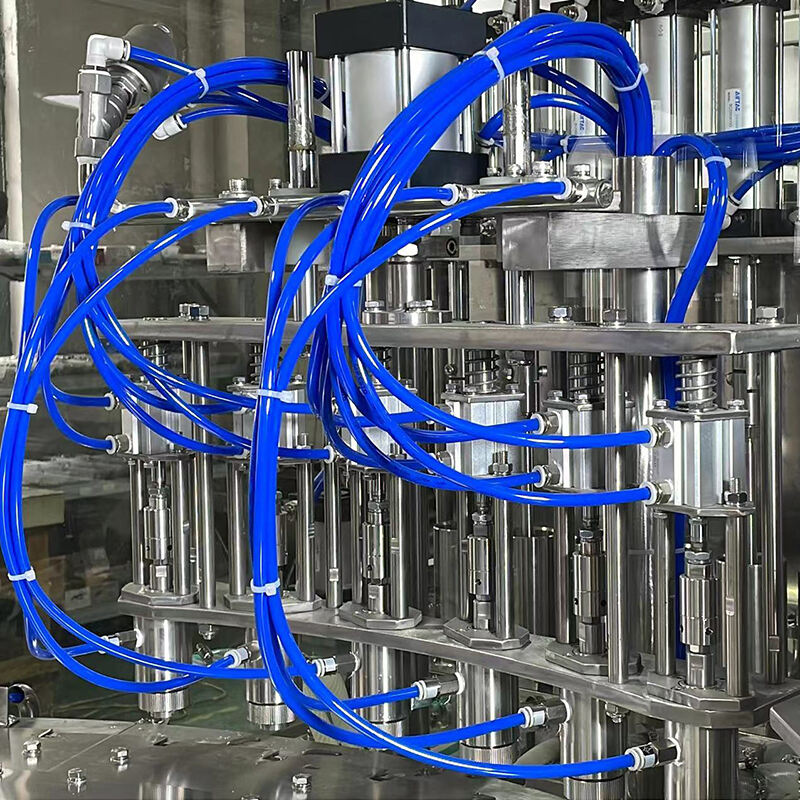

The spout capping machine is a state-of-the-art piece of equipment designed to efficiently seal spouts on liquid packaging. Its main functions include accurately placing spouts onto containers and ensuring a secure seal with the cap, which prevents any leakage or contamination. Technological features of this machine include precision sensors, an intuitive touch-screen interface, and programmable logic controllers that allow for seamless operation and easy adjustments. These features make the spout capping machine suitable for a variety of applications, including the packaging of beverages, detergents, and pharmaceuticals. With high-speed capabilities and reliability, it is an essential component in the production line for businesses looking to automate their packaging process.