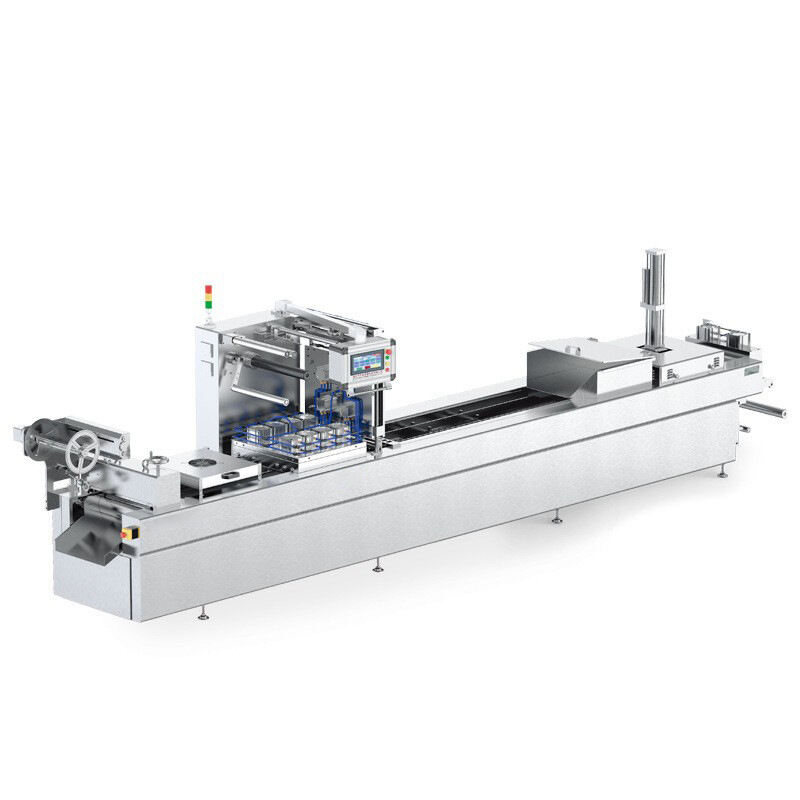

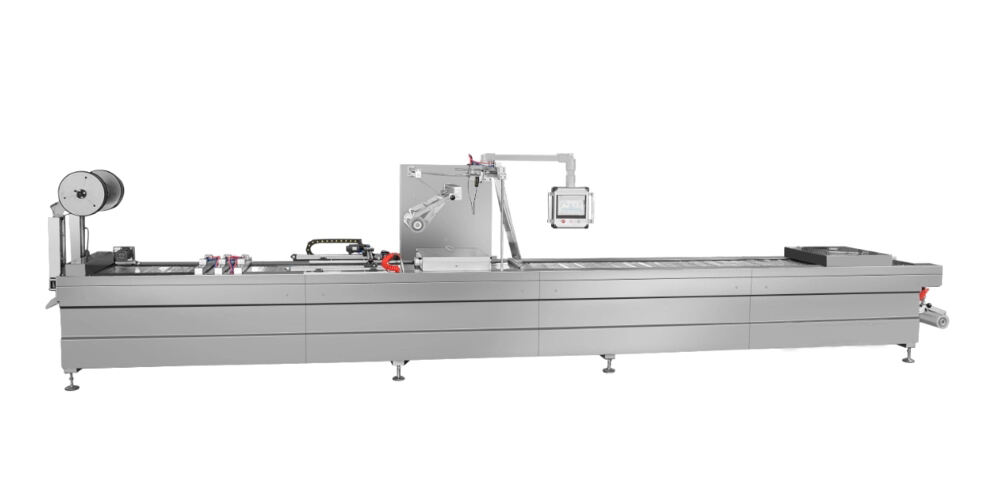

thermoforming vacuum machine

A thermoforming vacuum machine is a crucial piece of equipment used in the manufacturing process where plastic sheets are heated and formed into various shapes by applying vacuum pressure. The primary functions include heating the plastic sheet to a pliable state, using a mold to shape the material, and applying vacuum to draw the heated plastic over or into the mold. Technological features of these machines often involve dynamic heating systems that adjust power as needed for precise temperature control, real-time temperature tracking with high-accuracy sensors, and hybrid vacuum systems that combine the benefits of both impeller systems and vacuum pumps for efficient suction. Applications span across industries such as food packaging, medical technology, automotive parts, and retail displays.