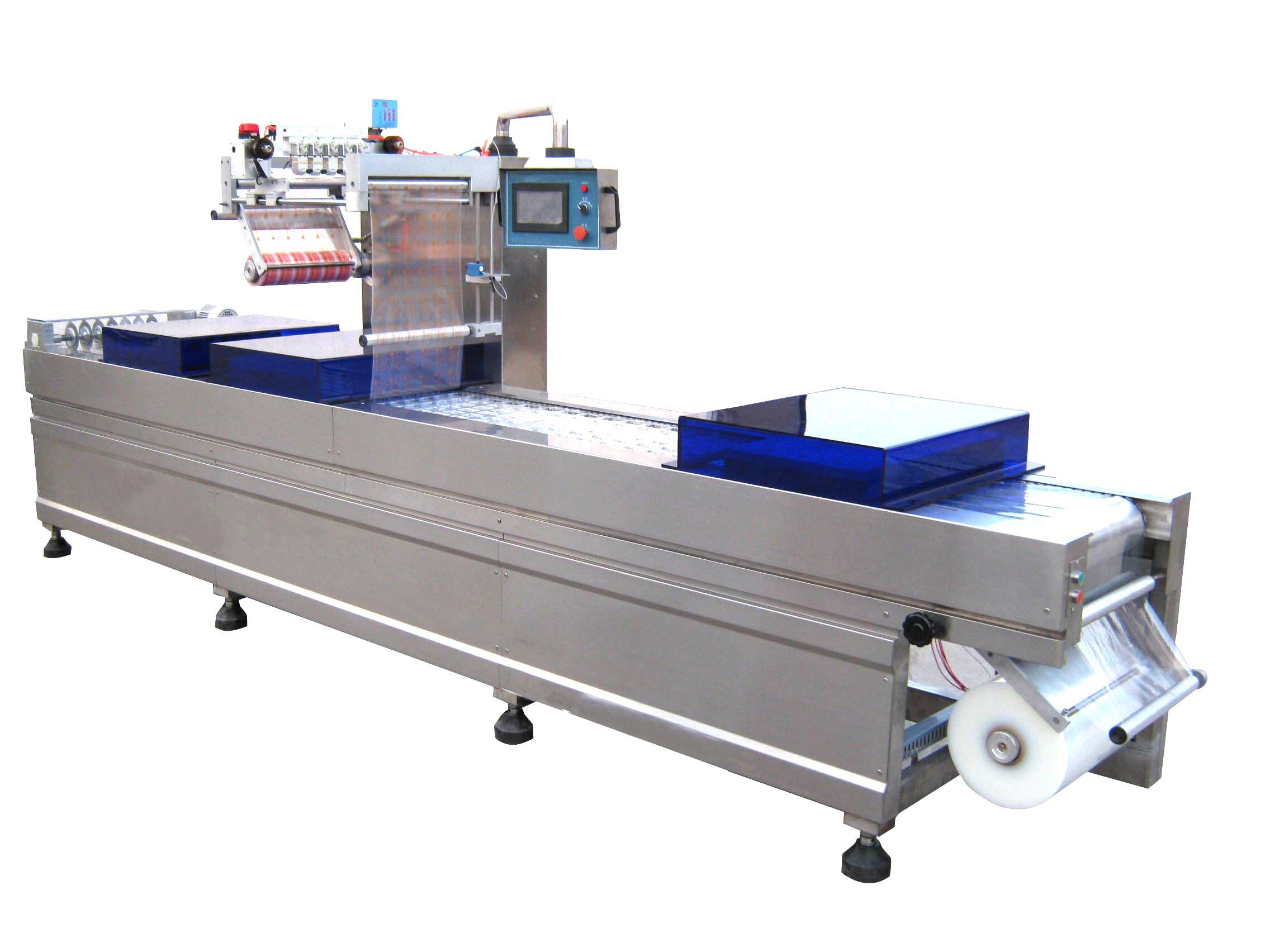

wet cat food cup filling and sealing machine

The wet cat food cup filling and sealing machine is a state-of-the-art solution designed to automate the packaging process of wet cat food products. This sophisticated equipment is engineered to perform main functions such as precise cup filling, efficient sealing, and rapid production to cater to the demands of pet food manufacturers. Technological features include a PLC-controlled system for accuracy and consistency, a hygienic stainless steel construction for easy cleaning and maintenance, and an advanced sensor system that ensures the correct quantity of product is dispensed. The machine's applications range from small-scale operations to large-scale production facilities seeking to enhance productivity and maintain high sanitation standards in their manufacturing processes.