Contact Info

1st Floor, Building 8, Yangluo Jinhao Industrial Park, Xinzhou District, Wuhan, China 430415

The automatic thermoforming packing machine is suitable for food packaging which can increase productivity, save manpower and save packaging materials.

The fully automatic stretch film vacuum packaging machine is called thermoforming packaging machine in the international market. It is named because it needs to use a roll of bottom film, and in the forming studio, it uses heating and vacuum negative pressure stretching technology to automatically form the roll film into a packaging bag. The fully automatic stretch film vacuum packaging machine is widely used in vacuum packaging of various foods and non-foods, and can quickly and high-quality meet the needs of large-scale and high-capacity vacuum packaging.

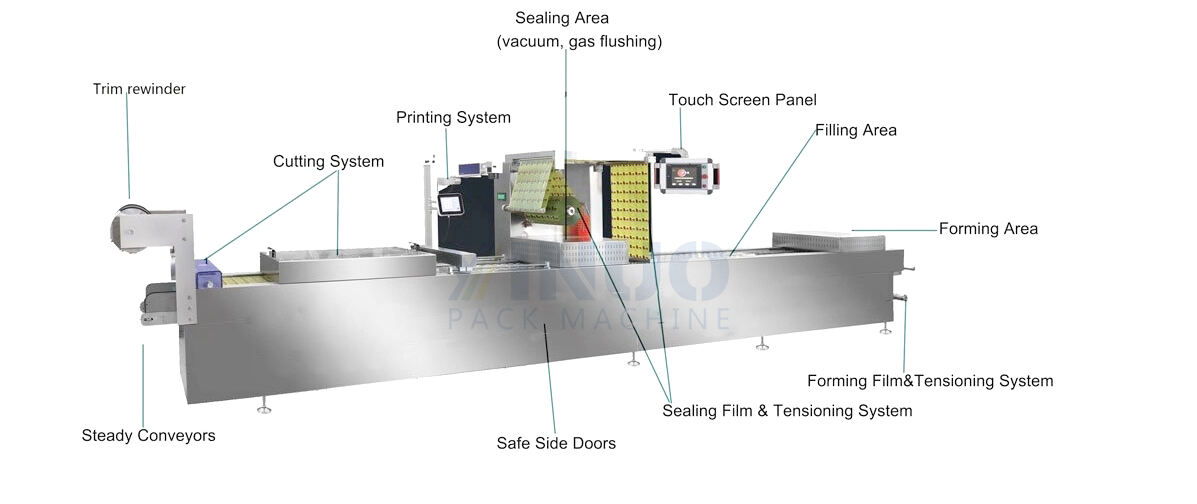

Composition of the fully automatic thermoforming vacuum packaging machine

1) Bottom forming film feeding system: ensure that the base film is installed in place, runs stably and is not biased;

2) Thermoforming system: forming studio, ensure that the base film is formed quickly, accurately and completely;

3) Filling area: can be filled manually, or can be equipped with automatic filling machines, multi-head scales and other automatic feeding equipment to achieve automatic filling;

4) Touch screen and PLC: most of the machine settings and operations can be completed through the touch screen, and faults can be found and eliminated;

5) Lining film feeding system: Liding film is the upper film, sealing film. The cover film can be a glossy film (without printing) or a color film. If it is a color film, the machine will be equipped with a high-precision photoelectric tracking system to ensure smooth and accurate film movement to achieve the desired packaging effect;

6) Vacuum sealing system: vacuum sealing studio, to ensure high vacuum and fast, tight sealing quality;

7) Pneumatic system: the pneumatic system is the power source for the molding and vacuum sealing studios to ensure that the upper and lower molds are tightly and neatly combined;

8) Slitting system: generally, the cross-cutting knife system performs horizontal cutting first, and then the longitudinal cutting knife system performs longitudinal cutting, and finally outputs the finished product. In special cases, such as when using hard film, or when there are special requirements for packaging, an integrated punching system is used to complete the punching in one go;

9) Waste film winding system: the cut waste film is recycled by this system, which is more environmentally friendly and easy to handle;

10) Inkjet coding system: to achieve printing of product information, date information, etc. Can be configured with an inkjet printer or a laser printer.