Contact Info

1st Floor, Building 8, Yangluo Jinhao Industrial Park, Xinzhou District, Wuhan, China 430415

New York.

Ice cup filling and sealing machine is a kind of equipment specially used for filling and sealing ice cups. It is widely used in ice production enterprises and some places where ice is needed, such as bars, restaurants, hotels, etc.

Ice cup filling and sealing machine is a kind of equipment specially used for filling and sealing ice cups. It is widely used in ice production enterprises and some places where ice is needed, such as bars, restaurants, hotels, etc.

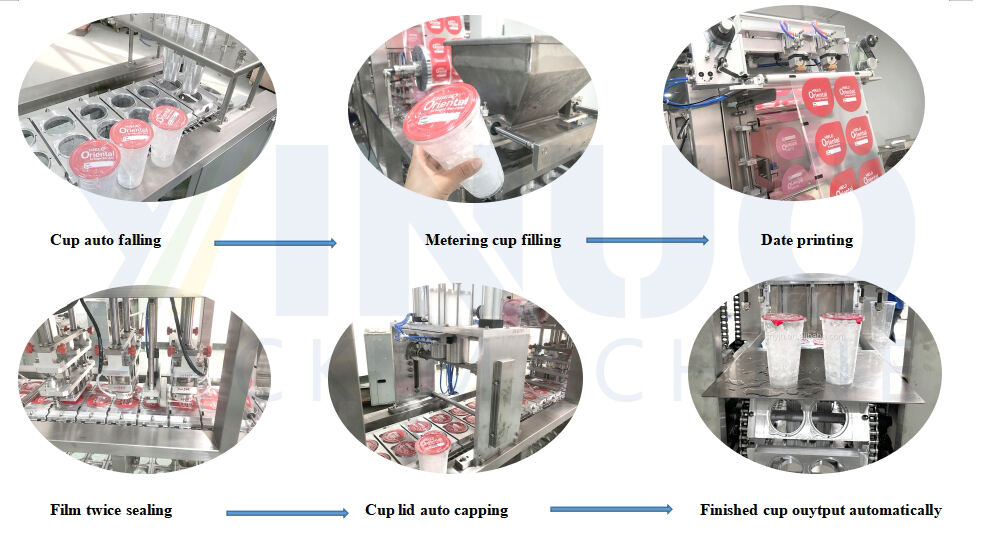

Working principle

Filling principle: Usually a quantitative filling system is used, and a motor drives a gear pump or piston pump and other devices to extract water from the water tank and accurately measure it, and then a certain amount of water is injected into the ice cup through the filling head. Some advanced filling and sealing machines are also equipped with liquid level sensors, which can adjust the filling volume according to the actual liquid level of the cup to ensure that the filling volume of each cup is accurate and consistent.

Sealing principle: Generally, heat sealing technology is used, and a heating element is used to heat the mouth of the ice cup to melt the cup mouth material (usually plastic film or aluminum foil, etc.), and then it is sealed on the cup mouth through a pressure device to form a tight seal to prevent the ice from melting and leaking during storage and transportation.

Equipment features

High degree of automation: It can automatically complete a series of processes such as loading, filling, sealing, and discharging of ice cups, reducing manual operations and improving production efficiency.

High filling accuracy: The use of advanced metering devices and control systems can accurately control the filling amount of water with a small error range to ensure that the weight of ice cubes in each ice cup is consistent.

Good sealing quality: Heat sealing technology can make the cup mouth seal firmly and not prone to leakage, effectively ensuring the storage and transportation quality of ice cubes.

Wide range of application: It can adapt to ice cups of different specifications and shapes. It only needs to replace the corresponding mold and adjust some parameters to meet a variety of packaging needs.

High hygiene standards: The equipment is made of food-grade stainless steel, meets hygiene standards, and is easy to clean and maintain, which can effectively prevent bacterial growth and contamination.