Contact Info

1st Floor, Building 8, Yangluo Jinhao Industrial Park, Xinzhou District, Wuhan, China 430415

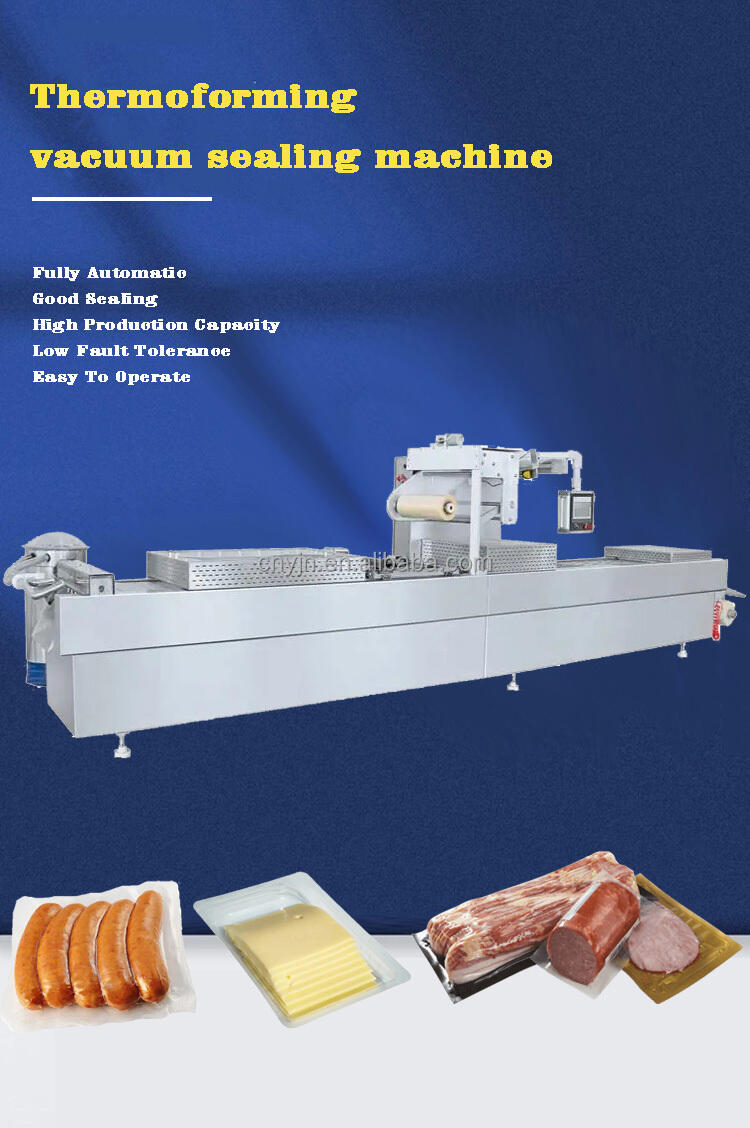

Thermoforming vacuum packaging machine is an advanced packaging equipment, mainly used for vacuum packaging of various products.

Thermoforming vacuum packaging machine is an advanced packaging equipment, mainly used for vacuum packaging of various Products.

Working principle

Thermoforming: Using the forming mold and heating system, the plastic film is heated to a softened state, and then it is formed into a container that matches the shape of the mold through mold stamping or blistering, etc., which is used to hold the product.

Vacuum packaging: The product is placed in the formed plastic container, and the vacuum system of the packaging machine starts to work, extracting the air in the packaging cavity, so that the packaging container reaches a predetermined vacuum degree, and then the heat sealing device seals the packaging container to complete the vacuum packaging process.

Structural composition

Film feeding system: responsible for providing plastic film, and accurately conveying the film to the forming station through the traction mechanism.

Heating and forming system: including heating elements and forming molds, which can heat, soften and stamp the film.

Vacuum and sealing system: composed of vacuum pump, vacuum chamber, heat sealing device, etc., to realize vacuuming and sealing functions.

Control system: usually adopts PLC programmable logic controller and touch screen operation interface, which can realize the setting and adjustment of various parameters of the packaging machine.

Conveying and unloading system: convey the formed and packaged products out of the packaging machine and unload them.

Features

High degree of automation: can automatically complete a series of packaging processes such as film forming, product filling, vacuum exhaust, sealing, etc., reduce manual operation and improve production efficiency.

Good packaging effect: can make the product and the packaging fit closely, effectively prevent the product from being squeezed, collided and damaged during transportation and storage, and the vacuum environment can also extend the shelf life of the product.

Wide range of applications: not only suitable for the packaging of various solid, liquid and semi-solid products in the food, medicine, electronics and other industries, but also can adapt to the packaging needs of products of different shapes and sizes.

Save packaging materials: Using plastic film as packaging material can reduce packaging costs compared with traditional packaging boxes, packaging bags, etc.

Application areas

Food industry: used for packaging of meat, seafood, fruits, vegetables, cakes and other foods to maintain the freshness and taste of food.

Pharmaceutical industry: can vacuum package medicines, medical devices, etc. to prevent medicines from getting damp and oxidized, and ensure the quality and safety of medicines.

Electronics industry: used for packaging of electronic components, circuit boards and other products to prevent electronic components from being affected by static electricity, dust, etc. during storage and transportation.