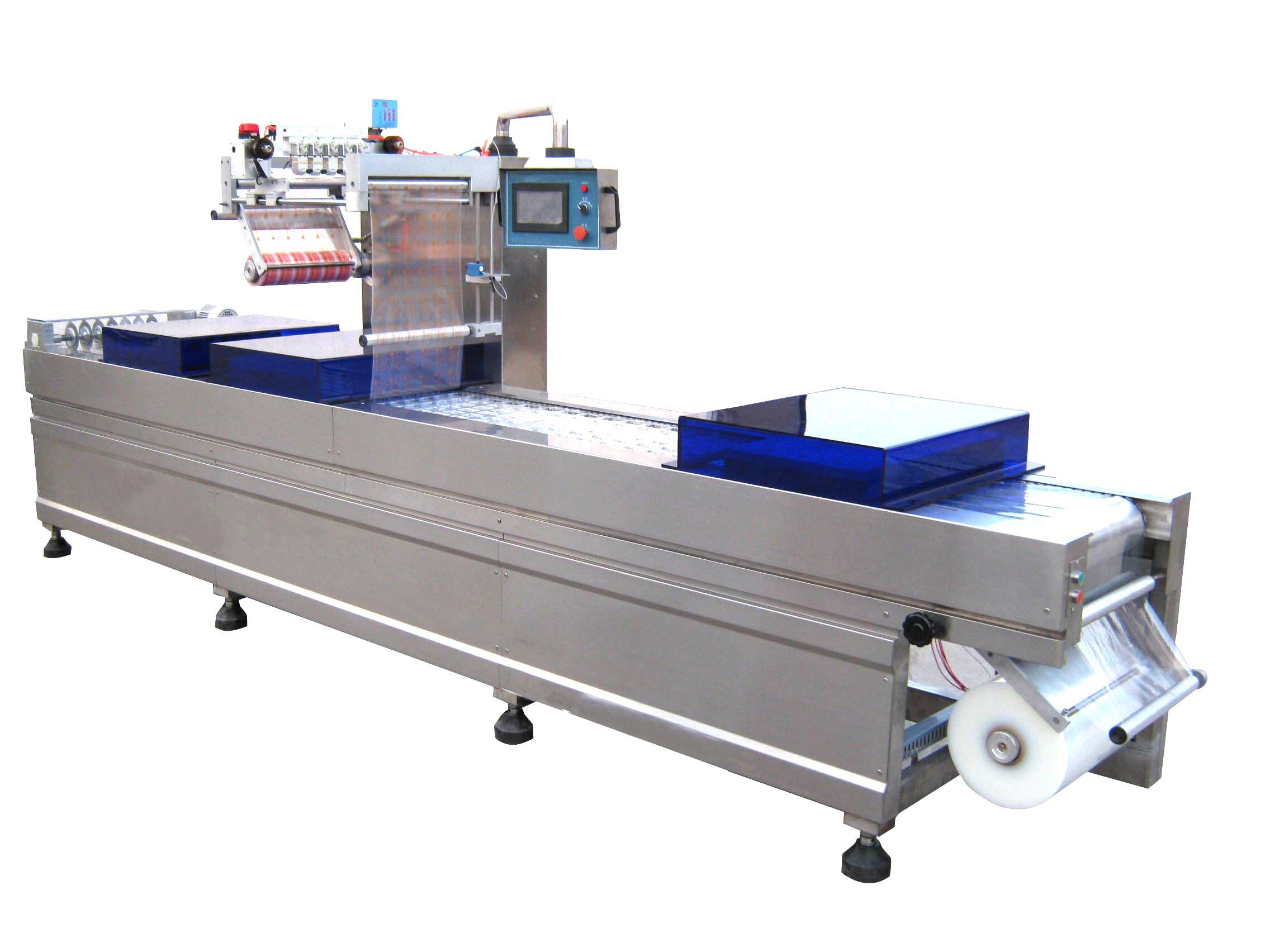

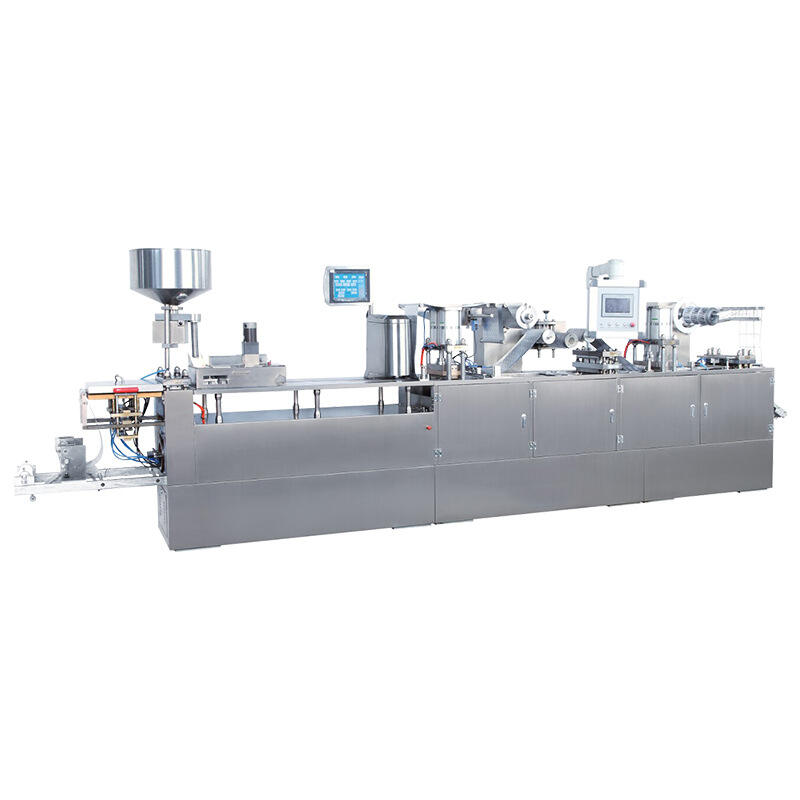

thermoform packaging machine

The thermoform packaging machine is a state-of-the-art solution designed to streamline packaging processes in various industries. Its main function is to heat a plastic sheet until it becomes pliable, then form it into a custom shape using a mold, and finally cut and seal it to create a secure package. Technological features include precise temperature control, automated feeding systems, and touch-screen interfaces for ease of operation. These machines are versatile, serving applications such as food packaging, medical device packaging, and consumer goods. With capabilities of high-speed production and the ability to handle a range of materials, the thermoform packaging machine is an indispensable tool for businesses aiming for efficiency and product presentation excellence.